pyGCodeDecode

pyGCodeDecode: A Python package for time-accurate GCode simulation in material extrusion processes - Published in JOSS (2024)

Science Score: 100.0%

This score indicates how likely this project is to be science-related based on various indicators:

-

✓CITATION.cff file

Found CITATION.cff file -

✓codemeta.json file

Found codemeta.json file -

✓.zenodo.json file

Found .zenodo.json file -

✓DOI references

Found 7 DOI reference(s) in README and JOSS metadata -

✓Academic publication links

Links to: joss.theoj.org, zenodo.org -

✓Committers with academic emails

5 of 5 committers (100.0%) from academic institutions -

✓Institutional organization owner

Organization fast-lb has institutional domain (www.fast.kit.edu) -

✓JOSS paper metadata

Published in Journal of Open Source Software

Keywords

Repository

Generate time dependent boundary conditions from a .gcode file.

Basic Info

Statistics

- Stars: 13

- Watchers: 0

- Forks: 2

- Open Issues: 0

- Releases: 17

Topics

Metadata Files

README.md

pyGCodeDecode

What is this repository for?

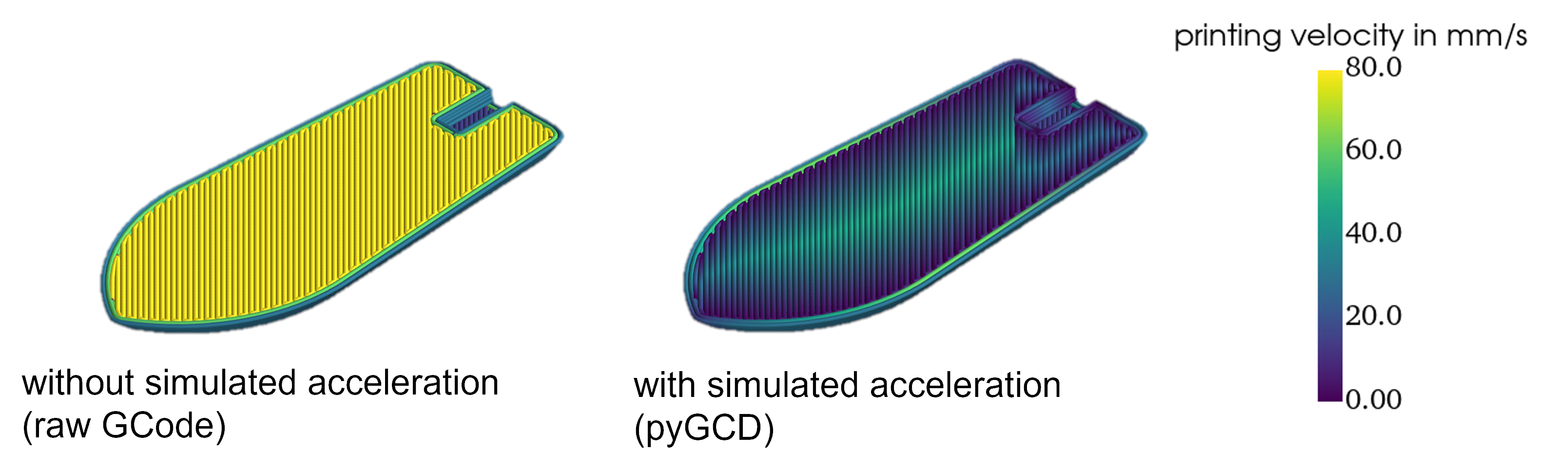

For the analysis of GCode, slicers or dedicated analyzer tools, such as Prusa Slicer or gCodeViewer, merely display target process parameters. The actual process velocity however is determined by the firmware of the printer. Velocities are expected to deviate significantly from the target velocity at times of acceleration and deceleration. pyGCodeDecode aims to model the machine's actual behavior and visualize its influence. A visual comparison between the simulated acceleration approach and the raw GCode target velocity is shown below.

This package reads the target trajectory firmware settings changes from a GCode file. Subsequently, it simulates a motion planner with acceleration and jerk or junction control respectively. The more accurate modeling is achieved by replicating grbl's and its derivatives' firmware-specific movement planner solutions, such as "Classic Jerk" and "Junction Deviation", as an interpretation for Jerk. The simulation result is a description of the nozzle and extrusion axis position and velocity over time and is easily accessible for further analysis. For example it can be used to generate time dependent boundary conditions, needed in additive manufacturing simulations for the Fused Filament Fabrication (FFF) process. The package includes 3D plotting functions, so it can be used to visualize local velocities before printing to improve your process understanding.

Install pyGCodeDecode

It is recommended that you first create a virtual Python-environment, e.g. using the venv-module built into Python. You can clone the repository and run

shell

pip install .

from inside the root directory. Alternatively you can simply install from PyPI:

shell

pip install pyGCodeDecode

If you plan to contribute to the development, install in development mode and with the additional dependencies:

shell

pip install -e .[DEVELOPER]

You may want to verify the installation and version. Inside your environment, just run:

shell

python -c "import pyGCodeDecode

print(pyGCodeDecode.__version__)"

This should return the correct version.

Running the CLI

pyGCD comes with a simplistic CLI to quickly run the provided examples or plot some G-Code without writing a script first. If you want to see something quickly, activate the venv where pyGCD is installed and run:

shell

pygcd run_example brace

You can also run and plot your own G-Code with:

shell

pygcd plot --gcode <PATH>

Creating a script using pyGCD

Example simulations are provided in ./examples/ and can be modified to suit your needs. If you want to start from scratch, the following instructions will help you setup and run a simulation.

Define your printer defaults in a .yaml file

For example, the definition may look like this: ./pyGCodeDecode/data/defaultprinterpresets.yaml:

yaml

prusa_mini:

# general properties

nozzle_diam: 0.4

filament_diam: 1.75

# default settings

p_vel: 35

p_acc: 1250

jerk: 8

# axis max speeds

vX: 180

vY: 180

vZ: 12

vE: 80

firmware: prusa

The default settings usually are machine specific and often can be read from the printer using a serial connection by sending a GCode command. You can use M503 for Marlin, Prusa and some other firmwares.

Use pyGCD to run a GCode Simulation

An easy way to use pyGCD is by creating a .py file to set up and run the simulation.

- Import the package and modules you want to use:

python

from pyGCodeDecode import gcode_interpreter

- Load your setup

.yamlfile through:

python

setup = gcode_interpreter.setup(filename=r"./pyGCodeDecode/data/default_printer_presets.yaml", printer="prusa_mini")

- You can optionally set or modify custom properties after loading the setup:

python

setup.set_property({"layer_cue": "LAYER_CHANGE"})

- Finally, run the simulation by providing a

GCodeand passing the setup defined before:

python

simulation = gcode_interpreter.simulation(filename=r"example\example.gcode", initial_machine_setup=setup)

Access the Results

The simulation object contains the simulation results, you can access them through various methods:

Get the individual axis values (position and velocity) at a certain time (e.g. after 2.6 s) to use it in further simulation by:

python

simulation.get_values(t=2.6)

You can visualize the GCode by plotting it in 3D:

python

from pyGCodeDecode.plotter import plot_3d

plot_3d(simulation)

pyGCD can also be used to create files defining an event series for ABAQUS simulations.

```python from pyGCodeDecode.abaqusfilegenerator import generateabaqusevent_series

generateabaquseventseries( simulation=simulation, filepath="path/to/eventseries.csv" ) ```

For more in depth information have a look into the documentation.

Supported GCode commands

Fully supported commands:

python

"G0": {"E": None, "X": None, "Y": None, "Z": None, "F": None}, # non extrusion move

"G1": {"E": None, "X": None, "Y": None, "Z": None, "F": None}, # extrusion move

"G4": {"P": None, "S": None}, # Dwell

"M82": None, # E absolute

"M83": None, # E relative

"G20": None, # inches

"G21": None, # millimeters

"G90": None, # absolute positioning

"G91": None, # relative positioning

"G92": {"E": None, "X": None, "Y": None, "Z": None}, # set position

";": None, # comment

Only partially supported commands:

python

"M203": {"E": None, "X": None, "Y": None, "Z": None}, # max feedrate *read only

"M204": {"P": None, "R": None, "S": None, "T": None}, # starting acceleration *P only

"M205": {"E": None, "J": None, "S": None, "X": None, "Y": None, "Z": None}, # advanced settings *X only

"G10": {"S": None}, # read only

"G11": None, # read only

Known unsupported commands that may cause issues:

python

"G2" : {-}, # clockwise arc/circle move, please disable this command in your slicer's settings

"G3" : {-}, # counter-clockwise arc/circle move, please disable this command in your slicer's settings

<!-- REFERENCES -->

Owner

- Name: FAST Lightweight Engineering @ KIT

- Login: FAST-LB

- Kind: organization

- Email: lt-github@kit.fast.kit.edu

- Location: Karlsruhe, Germany

- Website: https://www.fast.kit.edu/english/lbt/index.php

- Repositories: 1

- Profile: https://github.com/FAST-LB

Doing research for the development and process simulation of lightweight structures. 🏎️🚀✈️🩼➡️🪶

JOSS Publication

pyGCodeDecode: A Python package for time-accurate GCode simulation in material extrusion processes

Authors

Institute of Vehicle System Technology - Lightweight Engineering, Karlsruhe Institute of Technology (KIT), Rintheimer Querallee 2, Karlsruhe, 76131, Germany

Institute of Vehicle System Technology - Lightweight Engineering, Karlsruhe Institute of Technology (KIT), Rintheimer Querallee 2, Karlsruhe, 76131, Germany

Institute of Vehicle System Technology - Lightweight Engineering, Karlsruhe Institute of Technology (KIT), Rintheimer Querallee 2, Karlsruhe, 76131, Germany

Tags

GCode Simulation Material Extrusion Fused Filament Fabrication Fused Deposition Modeling Additive Manufacturing 3D Printing Machine Code Firmware FFF FDM MEX Process Simulation EngineeringCitation (CITATION.cff)

# This CITATION.cff file was generated with cffinit.

# Visit https://bit.ly/cffinit to generate yours today!

cff-version: 1.2.0

title: pyGCodeDecode

message: >-

This package reads the target trajectory firmware settings

changes from a GCode file. Subsequently, it simulates a

motion planner with acceleration and jerk or junction

control respectively. The more accurate modeling is

achieved by replicating grbl's and its derivatives'

firmware-specific movement planner solutions, such as

"Classic Jerk" and "Junction Deviation", as an

interpretation for Jerk. The simulation result is a

description of the nozzle and extrusion axis position and

velocity over time and is easily accessible for further

analysis. For example it can be used to generate time

dependent boundary conditions, needed in additive

manufacturing simulations for the Fused Filament

Fabrication (FFF) process. The package includes 3D

plotting functions, so it can be used to visualize local

velocities before printing to improve your process

understanding.

type: software

authors:

- given-names: Jonathan

family-names: Knirsch

email: jonathan.knirsch@student.kit.edu

affiliation: >-

Institute of Vehicle System Technology - Lightweight

Engineering, Karlsruhe Institute of Technology (KIT),

Rintheimer Querallee 2, Karlsruhe, 76131, Germany

orcid: 'https://orcid.org/0009-0008-8663-8721'

- given-names: Felix

family-names: Frölich

email: felix.froelich@kit.edu

affiliation: >-

Institute of Vehicle System Technology - Lightweight

Engineering, Karlsruhe Institute of Technology (KIT),

Rintheimer Querallee 2, Karlsruhe, 76131, Germany

orcid: 'https://orcid.org/0000-0002-2575-4752'

- given-names: Lukas

family-names: Hof

orcid: 'https://orcid.org/0009-0000-4931-2409'

affiliation: >-

Institute of Vehicle System Technology - Lightweight

Engineering, Karlsruhe Institute of Technology (KIT),

Rintheimer Querallee 2, Karlsruhe, 76131, Germany

email: lukas.hof@kit.edu

- given-names: Florian

family-names: Wittemann

email: florian.wittemann@kit.edu

affiliation: >-

Institute of Vehicle System Technology - Lightweight

Engineering, Karlsruhe Institute of Technology (KIT),

Rintheimer Querallee 2, Karlsruhe, 76131, Germany

orcid: 'https://orcid.org/0000-0001-8693-7264'

- given-names: Luise

family-names: Kärger

email: luise.kaerger@kit.edu

affiliation: >-

Institute of Vehicle System Technology - Lightweight

Engineering, Karlsruhe Institute of Technology (KIT),

Rintheimer Querallee 2, Karlsruhe, 76131, Germany

orcid: 'https://orcid.org/0000-0002-6534-6518'

identifiers:

- type: doi

value: 10.5281/zenodo.12663658

description: Zenodo archive

repository-code: 'https://github.com/FAST-LB/pyGCodeDecode'

repository-artifact: 'https://pypi.org/project/pyGCodeDecode/'

abstract: >-

For the analysis of GCode, slicers or dedicated analyzer

tools, such as Prusa Slicer or gCodeViewer, merely

display target process parameters. The actual process

velocity however is determined by the firmware of the

printer. Velocities are expected to deviate significantly

from the target velocity at times of acceleration and

deceleration. pyGCodeDecode aims to model the machine's

actual behavior and visualize its influence.

keywords:

- GCode

- Simulation

- Material Extrusion

- Fused Filament Fabrication

- Fused Deposition Modeling

- Additive Manufacturing

- 3D Printing

- Machine Code

- Firmware

- FFF

- FDM

- MEX

- Process Simulation

- Engineering

license: MIT

GitHub Events

Total

- Release event: 4

- Watch event: 5

- Delete event: 2

- Push event: 4

- Fork event: 3

- Create event: 4

Last Year

- Release event: 4

- Watch event: 5

- Delete event: 2

- Push event: 4

- Fork event: 3

- Create event: 4

Committers

Last synced: 7 months ago

Top Committers

| Name | Commits | |

|---|---|---|

| Lukas Hof | l****f@k****u | 232 |

| usmfi | u****i@s****u | 206 |

| Felix Frölich | f****h@k****u | 34 |

| usmfi | u****i@k****u | 18 |

| usmfi | j****h@s****u | 16 |

Committer Domains (Top 20 + Academic)

Issues and Pull Requests

Last synced: 6 months ago

All Time

- Total issues: 1

- Total pull requests: 1

- Average time to close issues: about 2 hours

- Average time to close pull requests: 4 minutes

- Total issue authors: 1

- Total pull request authors: 1

- Average comments per issue: 1.0

- Average comments per pull request: 0.0

- Merged pull requests: 1

- Bot issues: 0

- Bot pull requests: 0

Past Year

- Issues: 0

- Pull requests: 0

- Average time to close issues: N/A

- Average time to close pull requests: N/A

- Issue authors: 0

- Pull request authors: 0

- Average comments per issue: 0

- Average comments per pull request: 0

- Merged pull requests: 0

- Bot issues: 0

- Bot pull requests: 0

Top Authors

Issue Authors

- Extraweich (1)

Pull Request Authors

- lukashof (2)

Top Labels

Issue Labels

Pull Request Labels

Packages

- Total packages: 1

-

Total downloads:

- pypi 126 last-month

- Total dependent packages: 0

- Total dependent repositories: 0

- Total versions: 18

- Total maintainers: 1

pypi.org: pygcodedecode

Generate time dependent boundary conditions from a .gcode file.

- Documentation: https://pygcodedecode.readthedocs.io/

- License: MIT License

-

Latest release: 1.4.1

published 6 months ago

Rankings

Maintainers (1)

Dependencies

- actions/checkout v4 composite

- actions/upload-artifact v1 composite

- openjournals/openjournals-draft-action master composite

- actions/checkout v4 composite

- actions/download-artifact v4 composite

- actions/setup-python v5 composite

- actions/upload-artifact v4 composite

- pypa/gh-action-pypi-publish release/v1 composite

- actions/checkout v4 composite

- actions/setup-python v5 composite

- actions/upload-artifact v4 composite

- PyYAML *

- matplotlib *

- numpy *

- pyvista *